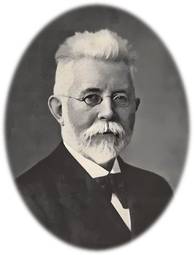

Articles about Malling-Hansen invention, The Xerography.

Xerografi - the world's first known dry copying method

When Rasmus Malling-Hansen wrote letters on his writing ball, he sometimes was in need of making several copies of his letters, and as always the brilliant mind of Malling-Hansen wanted to find a way of making several copies in one process, in stead of the usual way - to use carbonized paper and make one extra copy at the time.

In 1872 he invented the first known dry copying method, and he called it the Xerografi, the same name that several years later was used by the famous company. But the Malling-Hansen copying method has only got the name in common with the much later photocopying process. Malling-Hansen used oiled paper, and he placed the carbonized paper underneath the paper with the carbonized side turned upwards, and this way it was made a reverse imprint of the writing on the backside of the oiled paper. He wrote on 5 pairs of these papers at the time, and this way he had 5 "negatives" when he had finished writing.

He then put white sheets of paper between the reverse imprints and then rolled them twice through a satiner machine, and thus he had in a very short amount of time, made 5 copies. The oiled paper could be used up to 20 times, and in only ten minutes or so, he was able to make 100 copies of a letter.

Malling-Hansen experimented a lot with his method, using carbonized paper from different producers, and he soon discovered the unique qualities of the blue colour, called "Berliner Blau" - when using blue carbonized paper, he could make far more copies than with any other colour. He also tried to add different types of liquids to the imprint made on the oiled paper, and he found out that if he added water with a solution of soap, he did not need the relatively expensive satiner machine, but could use an ordinary paper press, which was much cheaper, and which most people who used an inkpen already had in their homes.

The inventor Malling-Hansen always thought about the practical issues in connection to his inventions, and so also with his dry copying method - the Xerografi.

Oslo, 02.12.06

Sverre Avnskog

Xerografi - Article in the Illustrated Journal 1872

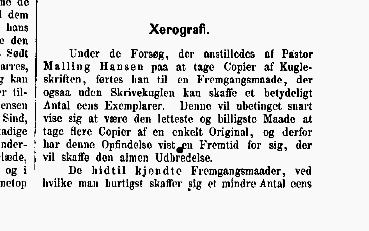

During Pastor Malling Hansens experiments with taking copies of the ball-print, he was lead to a method, which, also without the Writing Ball, can produce a significant number of identical copies.

This will undoubtedly soon prove to be the easiest and cheapest way to make several copies from one single original, and therefore this invention has probably a future ahead, which will make it very popular.

The present methods, by which one can quickly acquire a small number of identical copies, are limited to these two: On a piece of paper printed with copy ink is placed a piece of moistened translucent paper and both pieces are then squeezed in a copy press against each other, where by the print is printed on the underside of the translucent paper. Thus you have two identical copies and can, by once more printing of the original on translucent paper, get a third, but usually very blurred copy.

With the other method, which is particularly used in telegraph stations, a piece of paper is laid on a hard surface and on top of it a piece of ink paper with the coloured side downwards; on the ink paper is again laid a piece of writing paper and so on in 4 to 6 layers. With a hard pencil or an Agate-point (?) and under a somewhat hard pressure, one writes through all these layers, and thus gets so many identical copies as there is layers, generally not more than 6, if you use ordinary paper, but around 12, when you use silk paper.

The new method has, as its first step, some likeliness to the last mentioned method. Blue ink paper and 'writing through' is used. But instead of putting the writing paper in the bottom, and upon it the ink paper with the colour downwards, then the ink paper is laid at the bottom, with the colour upwards, and on top of it a sheet of oil paper, then ink paper with the colour upwards, then oil paper, ink paper and so on, eg in 5 layers.

These layers are written through, and you have thus 5 identical copies, on which the printing or the drawing is in reverse on that side of the sheets of paper which was downward during the printing.

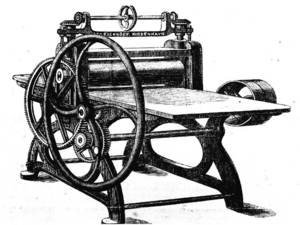

From each of these 5 copies can now be made not less than 20 reprints, giving 100 copies plus the 5 originals, in the following way: Between the 5 copies is laid writing paper, and this stack is passed through, under not too heavy pressure, the two rollers of a small Satineer machine.

The writing will then be printed on the 5 sheets of writing paper. Once more, 5 pieces of writing paper is placed between the already once used originals, and again they are passed through the rollers, but under a slightly heavier pressure, and now you have 10 copies. This printing can - with a constantly growing pressure of the rollers - indeed be repeated not less than 20 times, and all 100 copies can be produced in 6 or 7 minutes, and they are all clear and sharp, yes even the writing on the 5 originals stand very clear and clean, in spite of the fact that there, from their original colour, has been taken colour to 20 other copies. If you write through 10 originals in one time, you can make 200 identical copies in 10 minutes.

The new idea in this method rests on the lucky discovery which Pastor Malling Hansen made some time ago, that the writing from the mentioned blue ink paper u n d e r c e r t a i n c o n d i t i o n s can be printed many times without loosing its colour. The colour from black or brown or other kinds of ink paper only gives a few useable prints, whereas the blue paper, if it is of the very intensive colour called Berliner Blue, alone is capable of giving the surprisingly high number of prints.

Of the suggested conditions the following are the most important: The ink paper must be thin and the colour on it must be finely grinded, preferably much finer than the colour you usually buy. Next, the oil paper must be thin, hard and very dry; that the paper is saturated with oil and that it is hard and dry has the effect, that it can take up the colour from the ink paper without absorbing it, and is thus able to give it off again. Furthermore the writing paper, i.e. the paper that the copies are printed on, must not be striped or ribbed but even, but without being too smooth. Finally the first print must be made with the least possible pressure of the rollers of the Satineer machine, and the following prints under a little stronger pressure than the previous.

Furthermore it must be underlined, that while the job of the Satineer machine has, until now, only been to smoothen or glaze paper, then it now gets a new utilization, namely to produce dry prints, - where neither the book press, nor the copy press nor the lithographic press are as usable as the Satineer machine.

For the writing through, instead of a pencil or an agate-point, a small, flexible ivory stick is more usable or, when you only want 20 identical copies, and thus only need one original, an ordinary pen dipped in ink.

A new method should preferably have a new name, and it lies close, that the inventor has called the here described dry print - Tør Tryk (Dry Print) or Xerografi. Since one here uses writing paper for the prints and oil paper for the originals and since the writing stands in reverse on the oil paper, which - oil paper and reverse writing - otherwise belongs to the hitherto usual copying methods, then the new in this method has been clearly and not unwittingly described by the following statement by professor Holten: "Hitherto one has first written the originals and then taken the copies. Now one will make the copies first and then the originals afterwards."

While thus the former copying methods have only yielded from 2 to 12 identical copies, then the Xerografi can, in the same amount of time with only a few minutes extra, deliver a c o u p l e o f h u n d r e d identical copies, and this, when first the Satineer machine has been acquired, without any other cost than for the paper.

In comparison with the Autografi (?) or the lithographic overprint (?) the xerografi, when there is no need for a number of copies larger than around 200, again gets the advantage, due to its much greater speed and cheapness. and in particularly due to the fact, that one does not have to send what one has written out of the house, to get many copies, but can oneself and with great ease make the prints.

Xerografi is thus now the simplest, fastest and cheapest means to get many identical copies. For circulars, trade offerings, filling out of formula and schemes, note-writing for singing clubs, role-descriptions in theatres, for railway and telegraph companies, in government offices, in court offices, for multiplication of all kinds of drawings, for use in schools, for instructions, different tasks, a.s.o. a.s.o. Xerografi will be obvious.

About the importance of this event, only this:

A federation of railway companies has promised a prize for the simplest and cheapest method to multiply the freight cards used by the railways. It seems, that the Xerografi completely solves this task, and it should give us great joy, if our fellow countryman, who already with the Writing Ball has made his name well-known and respected abroad, by this new method will even more confirm the advantageous reputation, which everywhere has accompanied his invention, and which he has so fully deserved.

English translation by

Christian Barnholdt

Illustreret Tidende 1872 - article about the Xerography in Danish.

Aftenposten 1872.12.11.

Research, illustrationer og publicering af Sverre Avnskog.

Transskribering og kommentarer af Jørgen Malling Christensen.

SA: Aftenposten, norsk dagsavis, ble grunnlagt 14. mai 1860 av Christian Schibsted som Christiania Adresseblad. Navnet ble endret til Aftenposten fra og med 1. januar året etter. Opprinnelig var avisen en ren ettermiddagsavis, men den hadde både både morgen- og ettermiddagsutgaver fra 1865. Tradisjonelt har avisen vært regnet som konservativ, og har i dag en redaksjonell plattform som er "ideologisk forankret i et liberalkonservativt samfunnssyn". (Fra Wikipedia).

JMC: Aftenpostens artikel bygger på artiklen i ”Illustreret Tidende” den 8 december 1872 (se denne på vor side uder fanebladet ’Xerografi’) men er ikke identisk med den.

- - - - -

Ny Opfindelse.

Under de Forsøg, der anstilledes af den danske Pastor Malling Hansen paa at tage Kopier af Kugleskriften, har han ifølge en interessant meddelelse i sidste Nummer af ”Ill. Tid.” opfundet en Fremgangsmaade, der ogsaa uden Skrivekuglen kan skaffe et betydeligt Antal ens Exemplarer paa en simpel, hurtig og billig Maade. Den nye Fremgangsmaade har paa sit første Trin nogen Lighed med den nu brugelige Gjennemskrivning; der benyttes blaat Sværtepapir og Gjennemskrivning; men i Stedet for at lægge Skrivepapiret nederst og paa det Sværtepapiret med Farven nedad, saa lægges Sværtepapiret nederst og med Farven opad og oven paa det et Stykke Oliepapir, derovenpaa Sværtepapir med Farven opad, Oliepapir, Sværtepapir osv., f. Ex. i 5 Lag.

Disse Lag gjennemskrives og man har saa 5 ens Exemplarer, paa hvilken Skriften eller det Tegnede staar omvendt paa den Side, som under Gjennemskrivningen vendte nedad. Af hvert af disse 5 Exemplarer kan dernæst tages ikke mindre end 20 Aftryk, og faaes altsaa ialt 100 ens Exemplarer foruden de 5 Originaler, og det paa følgende Maade: Imellem de 5 Originaler lægges Skrivepapir, og denne Bunke føres under et ikke stærkt Tryk igjennem en lille Satinermaskines to Valser.

Skriften staar da aftrykt paa de 5 Stykker Skrivepapir. Atter lægges Papir mellem de en Gang benyttede Originaler, og atter føres de imellem Valserne, men under et lidt stærkere Tryk, og man har saa ialt 10 Exemplarer. Denne Aftrykning kan – under et voxende Tryk af Valserne – altsaa gjentages ikke mindre end 20 Gange, og alle de 100 Aftryk ere frembragte i 6 eller 7 Minuter, og der ere alle tydelige og skarpe, ja endog Skriften paa de 5 Originaler staar aldeles klar og ren, uagtet der af den Farve, Skrifttrækkene havde fra først af, er blevet afgivet Farve nok til hele 20 andre Exemplarer.

Gjennemskriver man 10 Originalexemplarer paa en Gang, kan man i Løbet af 10 Minuter have henved 200 ens Exemplarer. Til Gjennemskrivningen er en bøielig liden Elfenbenspind mest tjenlig. Hvad Papiret angaar, maa Sværtepapiret som anført være blaat; kun denne Farve kan nemlig efter Malling Hansens Forsøg give det nødvendige store Antal Aftryk. Den nye Opfindelse benævnes Tør-Tryk eller Xerografi.

- - - - -

Skandinavisk Bogtrykker-Tidende 1873.

Der Deutsche Correspondent 1873.01.13.

[1] Research, transcription and comments by Jorgen Malling Christensen.

Illustrasjoner ved Sverre Avnskog.

Malling-Hansen invented his copying method, Xerography, in 1872. It was presented in detail in a lengthy article in the Danish magazine “Illustreret Tidende”, issue of 8 December 1872, which can be found on our site, as well as an English translation of the text. The same article appeared simultaneously in the German version of the magazine.

It is likely that Malling-Hansen applied for and obtained patents for this method in Denmark and probably also in other countries, but we are yet to find these patents.

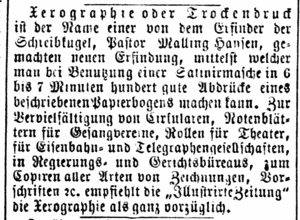

Xerographie oder Trockendruck ist der Name einer von dem Erfinder der Screibkugel, Pastor Malling Hansen gemachten neuen Erfindung, mittelst welcher man bei Benutzung einer Satiniérmaschine in 6 bis 7 Minut hundert gute Abdrücke eines beschriebene Papierbogens machen kann.

Zur Vervielfältigung von Circularen, Notenblättern für Gesangvereine, Rollen für Theater, für Eisenbahn- und Telegraphengesellschaften, in Regierungs- und Gerichtbüreaus, zum Copiren aller Arten von Zeichnungen, Vorschriften ec. empfielht die „Illustrirte Zeitung“ die Xerographie als ganz vorzüglich.

[1] JMC: This paper was published in Baltimore, Maryland, and is one of many similar examples of newspapers and magazines catering to the needs of the German settlers in America, arriving in the second half of the 19th century.

Badische Landes-Zeitung 1875.03.19.

Research, transcription and comments by Jørgen Malling Christensen.

Illustrations and publication by Sverre Avnskog.

Rasmus Malling-Hansen invented his copying method – named ‘xerografi’ (xerography) – in 1872, and that same year the Danish magazine ‘Illustreret Tidende’ had an article presenting the invention in its issue of 8 December, 1872. The German public could read about the new invention in ‘Der Deutsche Correspondent’, issue of January 13, 1873.

Our webside has a number of articles in Danish and English about the details of the method. The article in ‘Badische Landes-Zeitung’ of March 19, 1875, transcribed below, explains in detail how Malling-Hansen managed to make 100 copies of a text or a drawing in a short period of time.

We believe that Malling-Hansen applied for a patent, at least in Denmark, concerning the method, but we have not as yet found any such patent. Our research is ongoing.

- - - - -

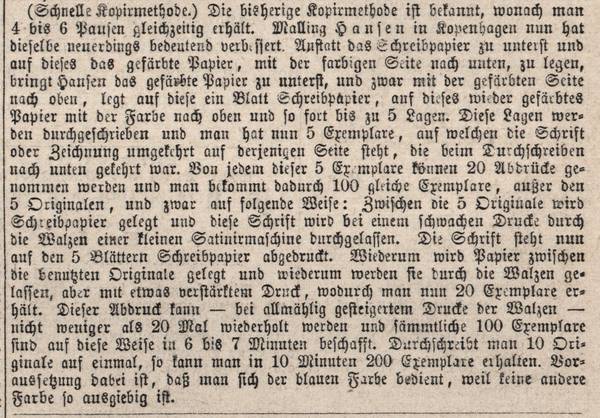

Schnelle Kopirmethode.

Die bisherige Kopirmethode ist bekannt, wonach man 4 bis6 Pausen gleichzeitig erhällt. Malling Hansen in Kopenhagen nun hat dieselbe neuerdings bedeutende verbessert. Anstatt das Schreibpapier zu unterst und auf dieses das gefärbte Papier, mit der farbigen Seite nach unten, zu liegen, bringt Hansen das gefärbte papier zu unterst, und zwar mit der gefärbten Seite nach oben, legt auf diese ein Blatt Schreibpapier, auf dieses wieder gefärbtes Papier mit der Farbe nach oben und so fort bis zu 5 Lagen.

Diese Lagen werden durchgeschrieben und man hat nun 5 Exemplare, auf welchem die Schrift oder Zeichnung umgekehrt auf derjenigen Seite steht, die beim Durchscreiben nach unten gekehrt war. Von jedem diser 5 Exemplare können 20 Abdrücke genommen werden und man bekommt dadurch 100 gleiche Exemplare, außer den 5 Originalen, und zwar auf folgende Weise: Zwischen die 5 Originale wird Schreibpapier gelegt und diese Schrift wird bei eninen schwachen Drucke durch die Walzen einer kleinen Satinirmaschine durchgelassen.

Die Schrift steht nun auf den 5 Blättern Schreibpapier abgedruckt. Wiederum wird Papier zwischen die benutzten Originale gelegt und wiederum werden sie durch die Walzen gelassen, aber mit etwas verstärkten Druck, wodurch man nun 20 Exemplare erhält. Dieser Abdruck kann – bei allmählig gesteigerten Drucke der Walzen – nicht weniger als 20 Mal wiederholt werden und sämmtliche 100 Exemplare sind auf diese Weise in 6 bis 7 Minuten beschafft. Durchschreibt man 10 Originale auf einmal, som kan man in 10 Minuten 200 Exemplare erhalten. Voraussetzung dabei ist, daß man sich der blauen Farbe[1] bedient, weil keine andere Farbe so ausgiebig ist.

[1] JMC: Die Name dieser farbe ist ‘Berliner Blau‘

Tørkopiering – artikel af Christian Barnholdt i Jyllandsposten 3 september 1990.

Research, transskribering og kommentarer af Jørgen Malling Christensen.

Illustrasjoner ved Sverre Avnskog.

Denne artikel blev skrevet af initiativtageren til vort selskab og vor første president: Christian Barnholdt, 1945-2015, og publiceredes i Jyllandsposten den 3 september 1990. Artiklen var et led i Christians anstrengelser for at minde danskerne om Rasmus Malling-Hansens store indsatser som opfinder, pædagogisk fornyer, videnskabsmand – og meget andet! Samtidig vidner artiklen også om Christians store og ihærdige arbejde på dette tidlige tidspunkt for at spreda kundskab og opmærksommhed om Rasmus Malling-Hansens liv og virke.

Jeg fandt artiklen i slægtsarkiver i oktober 2021.

Trods mange års søgning har vi endnu ikke fundet nogen eneretsbevilling eller ansøgning vedrørende Malling-Hansens kopieringsmetode. Det er dog rimeligt at antage, at han ansøgte om dansk eneret for den, og vor forskning fortsætter ad dette spor.

Se også vor dokumentation – under fanebladet ’xerografi’ – af Malling-Hansens norske patent i december 1873 på en metode, som er teknisk sammenhængende med xerografien, nemlig 10 års patent for ”papirets tørring i Plan ved Uhrverk og Elektromangetisme”.

Se videre artiklen af Jan Eskildsen, publiceret i tidsskriftet Aktuel Grafisk Information 1998.

- - - - -

Tørkopiering – en verdenssucces opfundet af en miskendt dansker.

Teknik/EDB

Cand.polit.

Christian Barnholdt

Hele verden tror, at tørkopieringen er en amerikansk opfindelse. Det er den ikke, Cand.polit. Christian Barnholdt dokumenterer her, at opfindelsen blev gjort af en dansker 65 år før den amerikaner, der tilskrives æren, kom på ideen. Den 27. i denne måned er det 100 år siden den danske opfinder døde – anerkendt af sin samtid, glemt af eftertiden, ignoreret af historien.

Tør-fotokopieringen er opfundet i Danmark, 65 år før man hidtil har troet.

Ordet ”xerografi” kommer fra græsk og betyder ”tør-kopiering”. Det er det princip, der ligger bag fotokopieringsmaskinerne.

Og ordet har givet navn til én af verdens største virksomheder, Xerox Corporation. Xerox overtog nemlig i 1937 de patenter, som svensk-amerikaneren Chester Karlson havde fået på en ny opfindelse – den elektrostatiske proces – som han kaldte for ”xerografi”. Patenterne gav Xerox eneret på teknikken i så mange år, at firmaet blev så stærkt identificeret med fotokopieringen, at en fotokopi endnu i dag i USA kaldes ”a xerox”.

I samtlige moderne leksika, og i Xerox’ egen historieskrivning, bliver 1937 udpeget som det år, xerografien blev opfundet, og æren herfor bliver tildelt Chester Karlson.

Men historikerne tager fejl. Der er bevis for, at en dansker allerede i 1872 opfandt tørkopieringen og døbte sin opfindelse ”xerografi”.

Opfinderen var Rasmus Malling-Hansen, der levede fra 1835 til 1890. Hans baggrund var højst usædvanlig for en opfinder, idet han var uddannet som skolelærer og teolog og var forstander for det Kongelige Døvstummeinstitut i København.

Men han havde en utrolig fantasi og en enestående evne til at tænke i nye baner og frigøre sig fra den tilvante måde at gøre tingene på. Hans kendskab til de døves fingersprog førte ham således til opfindelsen af verdens første skrivemaskine, skrivekuglen, i 1867.

Og, som en direkte følge deraf, opdagade han i 1872, at man kunne tage kopier af et brev eller en tegning ved hjælp af blåt karbonpapir og en valse.

Da han havde en teologisk uddannelse, var det nemt at vælge betegnelsen for den nye teknik, han havde opfundet: Xerografi – fra græsk xero (tør) og grafi (tryk).

Opfindelsen blev offentliggjort i Illustreret Tidende i november 1872. (På side 91 og 92, 14.årgang 1872/73).

Her beskrives i detaljer, hvorledes han opdagede tørkopieringen ved at lægge et bundt af skiftevis hvidt papir og karbonpapir med bagsiden opad, ind under skrivekuglen. Karbondpapirets aftryk kom således spejlvendt på undersiden af de hvide ark.

Han opdagede endvidere, at når man tog disse hvide ark, med spejlskrift på undersiden, lagde ubeskrevne hvide ark imellem dem og førte hele bundtet mellem to valser, så blev teksten kopieret over på de hvide ark.

Og han opdagede, at denne kopieringsproces kunne gentages mange gange med de samme originale kopier, hvis man hver gang øgede trykket i valserne – altså mindskede afstanden mellem dem.

Han opdagede endvidere, at den blå farve var specielt velegnet til denne massekopiering. Brunt og sort gav kun mulighed for at gentage trykningen fire-fem gange. Men med ”berlinerblåt” kunne hver ”kopi” trykke 20 ”originaler”.

I forhold til datidens kendte metoder til at kopiere breve, der alle var baserede på indviklede ”vådkopieringsmetider”, var Malling-Hansens opfindelse sensationel. Den ”valsemaskine” han brugte var en ”satinermaskine”, der ellers blev brugt til at udglatte papir. Hvorfor Malling-Hansen havde en sådan maskine derhjemme, fortæller historien ikek noget om. Det var dog formodentlig et betydeligt simplere apparat end vist på billedet. Ingen danske museer har i dag en ”satinermaskine” stående, og dens brug er helt ukendt.

På fem minutter kunne Malling-Hansen tage 100 kopier af ikke blot breve, men også af fx kort eller tegninger.

Malling-Hansen havde altså gjort flere helt nye opdagelser, ikke mindst at den blå farve har den enestående egenskab at beholde sin kraft ved aftrykning langt bedre end andre farver. At vende sværtepapiret om, så der skrives spejlvendt, er også hans idé! Selve ordet ”xerografi” er også hans ”opfindelse”. Og at man kunne kopiere mange flere gange ved at anvende valser med stigende tryk er vist også Malling-Hansens opdagelse.

Kopieringsprincippet var selvfølgelig for længst opfundet af Gutenberg. Ethvert trykkeri kunne kopiere en tekst ved hjælp af en blysats og en bogtrykspresse. Men denne metode var meget besværligere, langsommere og dyrere en den ”hjemmekopiering” som ”xerografien” nu muliggjorde.

Derfor blev Malling-Hansens opfindelse i Illustreret Tidende spået en meget stor fremtid.

”Medens de tidligere copierings-maader kun kunde give fra 2 til 12 eens exemplarer, saa kan xerografien levere et par hundrede eens exemplarer, og det, naar først satinermaskinen er anskaffet, uden anden udgift end til papiret. Xerografien er altså nu det simpleste, hurtigste og billigste middel til at skaffe sig mange eens exemplarer af f.eks. circulairer, handelstilbud, formularer og schemaer, til nodeskrivning, til rolleafskrivning for theatre, til brug for jernbane- og telegrafselskaber, i regerings-contoirer, til mangfoldiggjørelse af alle slags tegninger, til brug i skoler osv. osv.”

Men sådan gik det ikke. Malling-Hansens sensationelle opdagelse af ”xerografien” kom aldrig længere. Det gik på samme måde som skrivekuglen. Af ukendte grunde blev den ikke den succes, som datiden forudså. Måske var Malling-Hansen for tidligt ude, som det var tilfældet med skrivekuglen, før der var et marked for hans opdagelse.

Men det er ubestrideligt, at opfinderen af begrebet ”xerografi” ikke er Chester Karlson, men Rasmus Malling-Hansen.

Følgende kilder indeholder de korrekte oplysninger om xerografiens opfindelse:

Opfindernes Liv, fra 1914, af Helge Holst.

Meyers Leksikon fra 1924, genoptrykt i 1970.

Alle senere leksika mangler helt opfinderens navn eller giver Chester Karlson æren for xerografien.

Malling-Hansens indsats burde have skaffet ham en permanent plads i verdenshistorien. Han var en af Danmarks allerstørste opfindere gennem tiderne, men døde skuffet og bitter i 1890 i en alder af kun 55 år.

Forhåbentlig kan denne artikel hjælpe til omsider at give ham den plads i historien, som han fortjener, og som hans samtid indså, at han var berettiget til. Men som han aldrig fik.